Good news | JPT won another industry award

On August 28th, the award ceremony for the "Weike Cup • OFweek 2024 Laser Industry Annual Selection", hosted by OFweek Weike Network, was grandly held in Shenzhen.

JPT's 300W Mopa Fiber Green Laser and Square Beam Output Semiconductor Laser were respectively honored with the Best Fiber/Disc Laser Technology Innovation Award and the Best Laser Industry Application Case Award.

Following the "Red Light Award," JPT's 300W Mopa Fiber Green Laser once again received industry recognition. This not only demonstrates high recognition for JPT's Mopa laser technology but also provides strong affirmation of JPT's laser technical strength.

OFweek 2024 Laser Industry Annual Selection

Ms. CC, JPT's Marketing Director, received the award as a representative (5th from left)

01

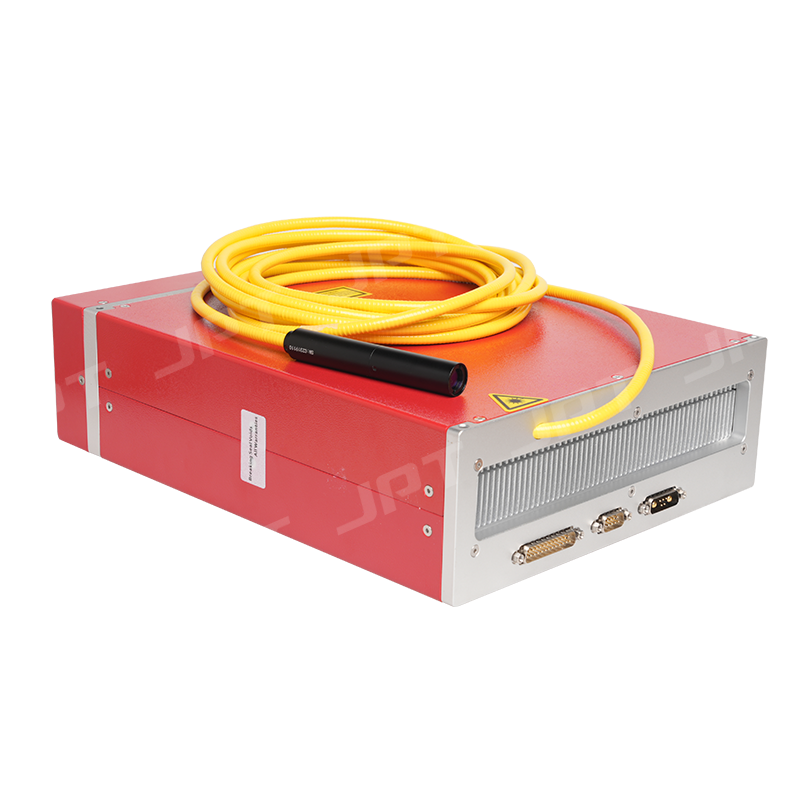

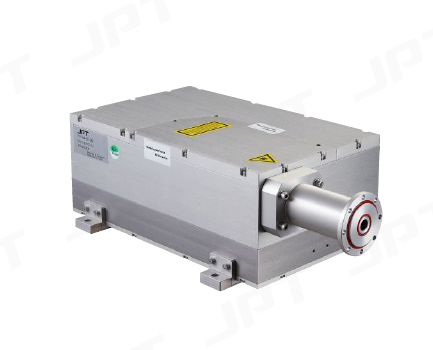

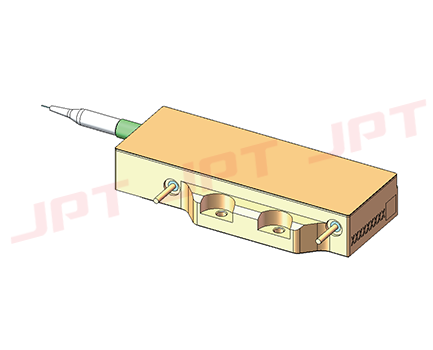

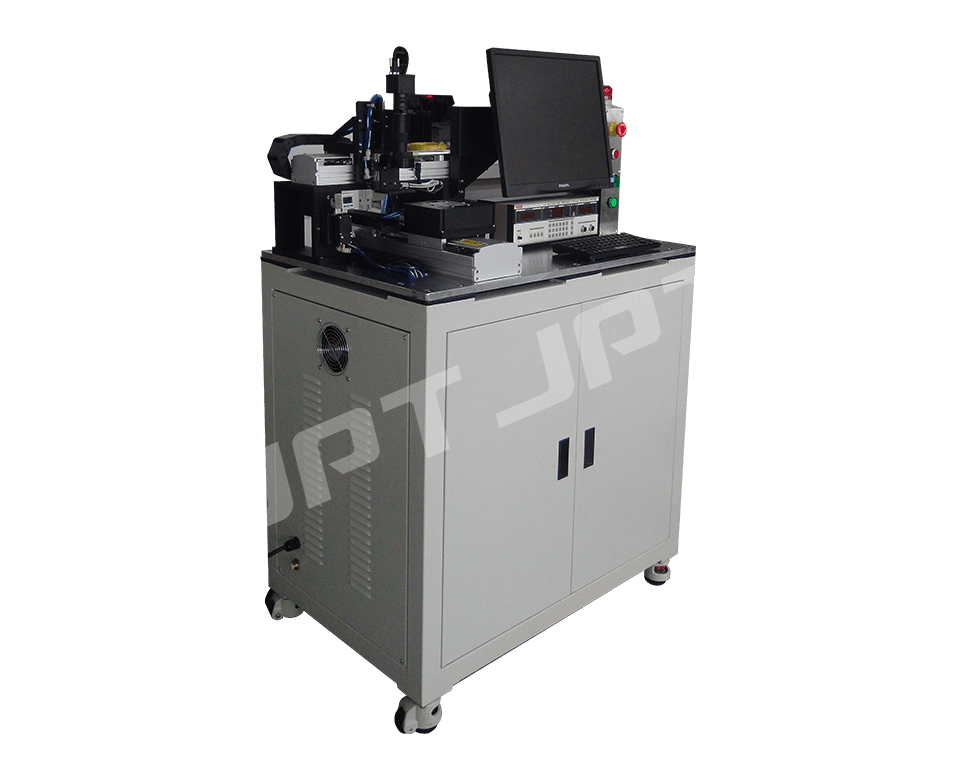

✦ 300W Mopa fiber green laser

JPT 300W Mopa fiber green laser can be used for low-energy fine processing such as power battery welding, liquid film cutting, and photovoltaic cell slotting. The principle is to use the gain-switch semiconductor laser as the seed source to generate nanosecond short pulses, use polarization-maintaining double-clad fiber and multi-mode semiconductor laser to construct polarization-maintaining fiber amplifier, and use multi-stage pulse amplification technology, cladding pump beam combination technology and large-mode field special fiber fusion technology to achieve 100-watt near-infrared pulse output. The LBO crystal is used as a frequency doubling device to control the near-infrared pulse parameters and match the design crystal parameters, and the near-single-mode green Mopa laser output with an average power of 300W is realized through extracavity frequency doubling.

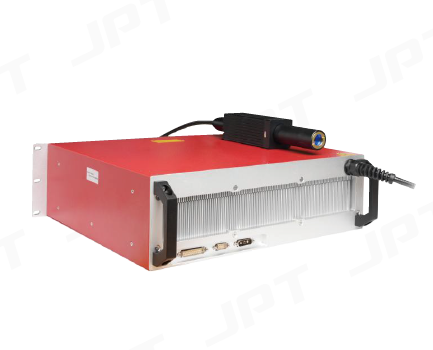

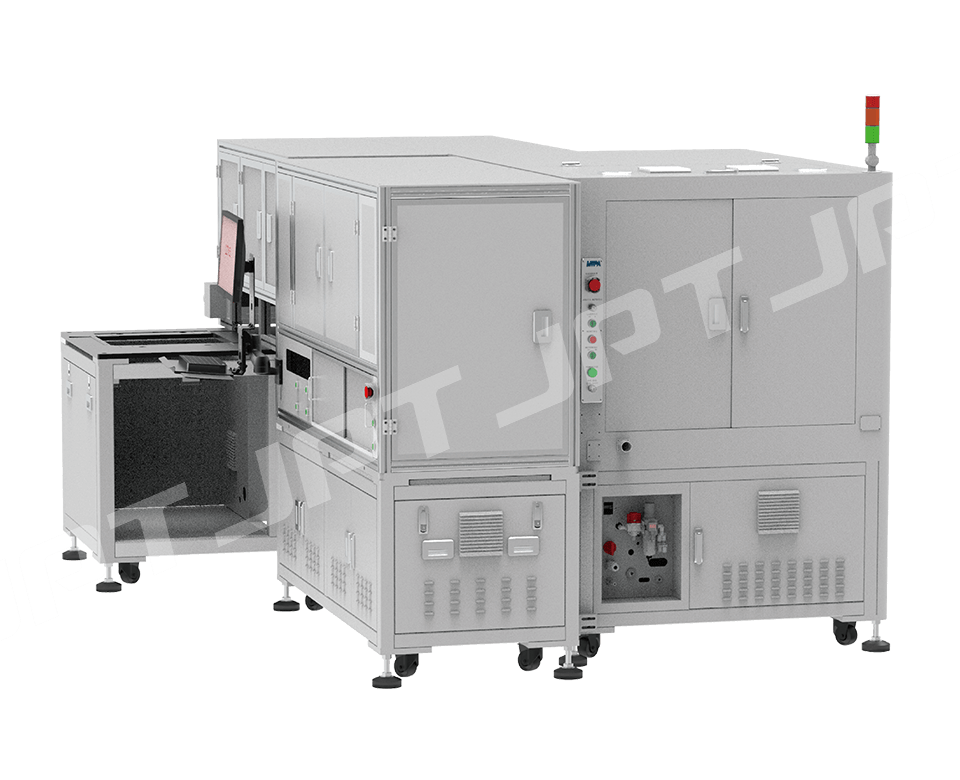

JPT 300W Mopa Fiber Green Laser

02

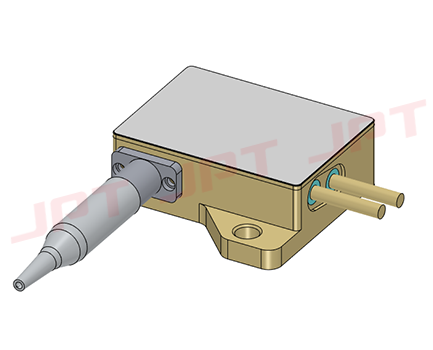

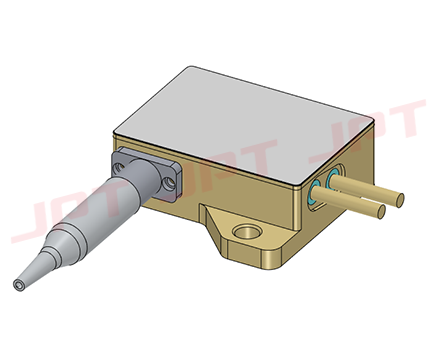

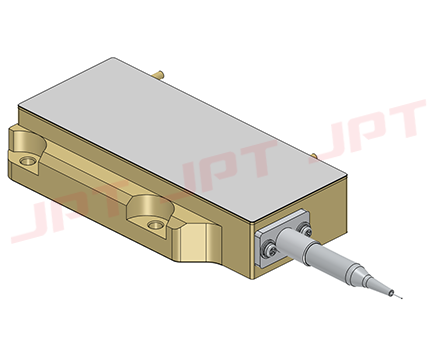

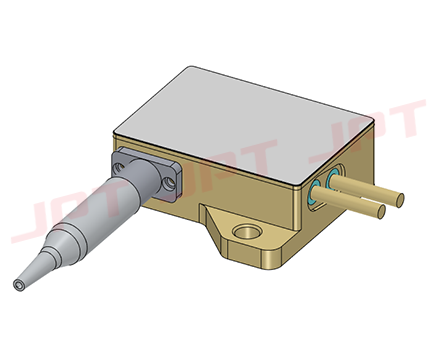

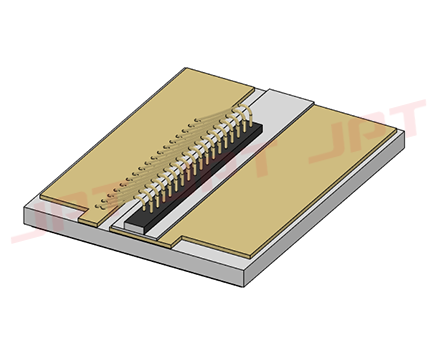

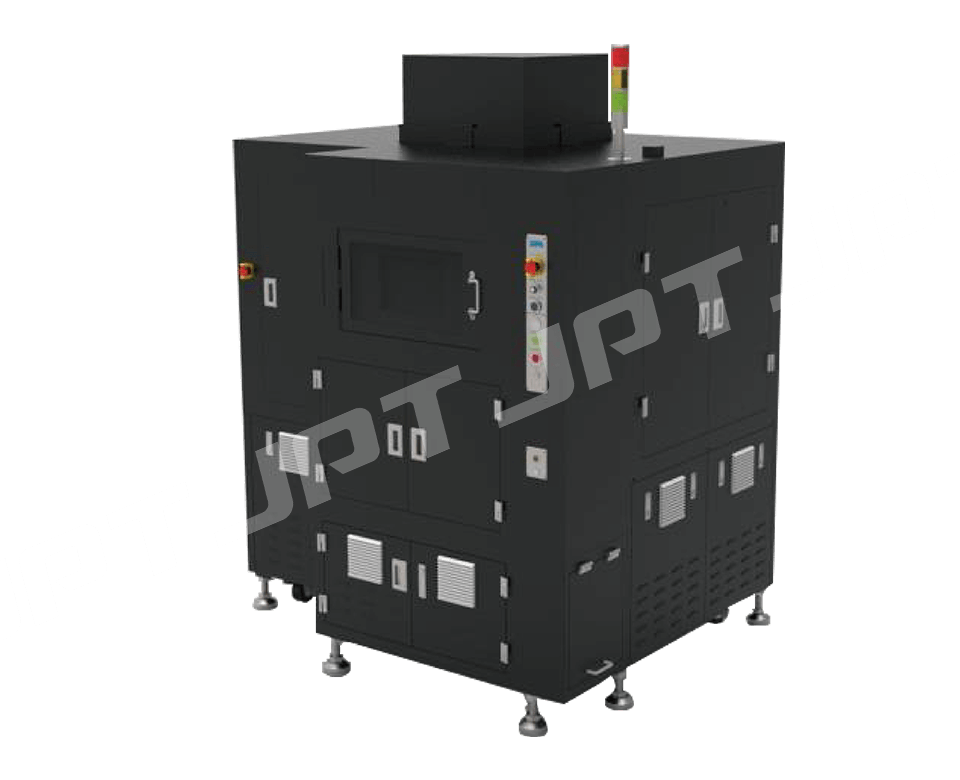

✦ Rectangular spot output diode laser

The square spot output semiconductor laser is a semiconductor laser independently developed and produced by JPT for defect detection of photovoltaic cells. The principle is to use the intact silicon structure to produce near-infrared fluorescence due to laser induction, and capture the fluorescence imaging through the near-infrared photosensitive camera, and analyze the image through the imaging effect to judge whether the silicon wafer is qualified. Using air-cooled heat dissipation mode, real-time monitoring of semiconductor laser temperature, over-temperature protection and other functions, output frequency, duty cycle, output power and other related parameters can be set, the output head is with the area array lens to achieve uniform area array spot output, compared with linear lasers, area array lasers can perfectly detect the defects of light and dark silicon wafers in photovoltaic applications, and can meet 7x24h continuous work.

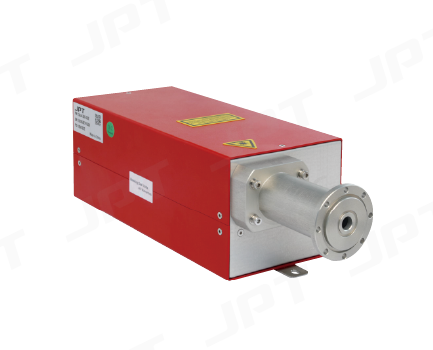

JPT Rectangular spot output diode laser

As China's first commercial manufacturer of high-power fiber lasers with adjustable pulse width, JPT will continue to deepen its core laser technology, focus on laser core modules, and provide customers with laser solutions in key areas such as consumer electronics and new energy, so as to help customers achieve intelligent manufacturing.

Recommended content

JPT 2024 Annual Report: Revenue Reaches a Historic High

DateTime:2025/04/03

JPT Skills Competition 2024 comes to a successful conclusion

DateTime:2024/11/13

"The Unseen Champion" Chronicle: JPT Strives to be the Leader in the Laser Technology Subdivision

DateTime:2024/08/30

Good news | JPT won another industry award

DateTime:2024/08/29

Good News | JPT Once Again Awarded National Manufacturing Industry Champion, Laser Resistor Technology Attracts Global Attention

DateTime:2024/08/19

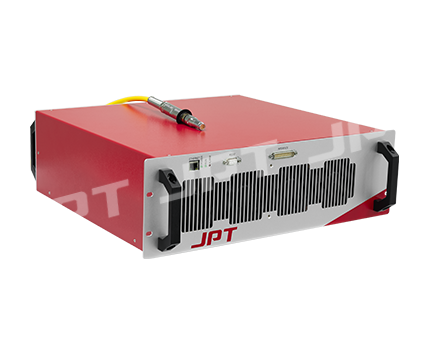

M7 20W-100W

M7 20W-100W

M7 200W-300W

M7 200W-300W

M7 500 - 1000W

M7 500 - 1000W

M8 20 - 50W

M8 20 - 50W

M8 120 - 300W

M8 120 - 300W

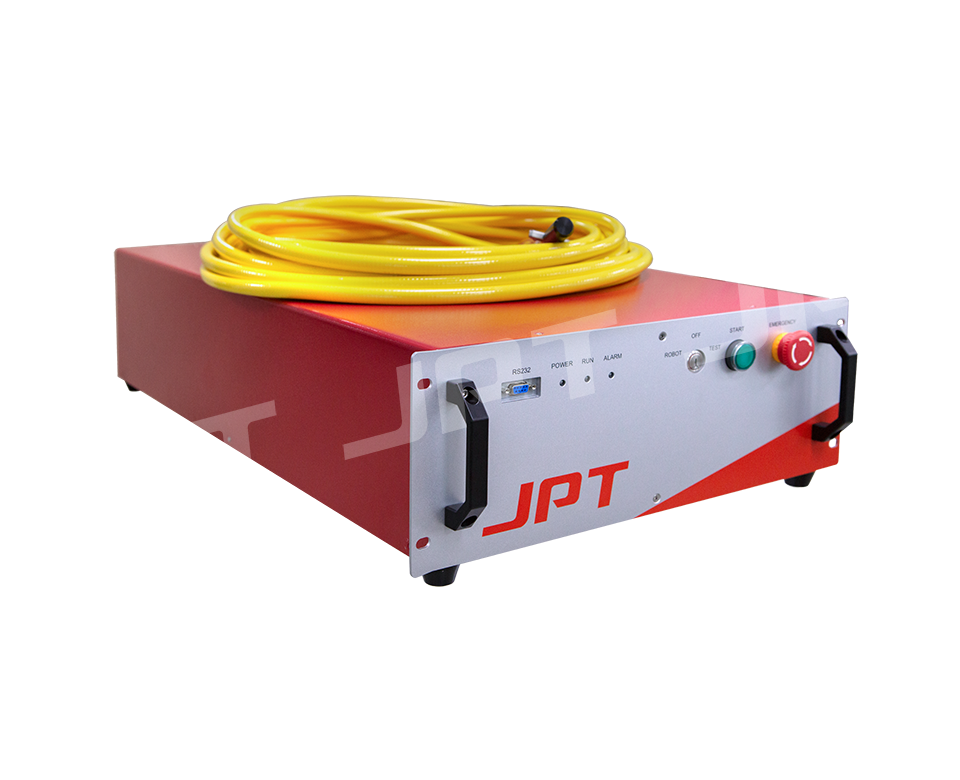

CL2 200W-300W

CL2 200W-300W

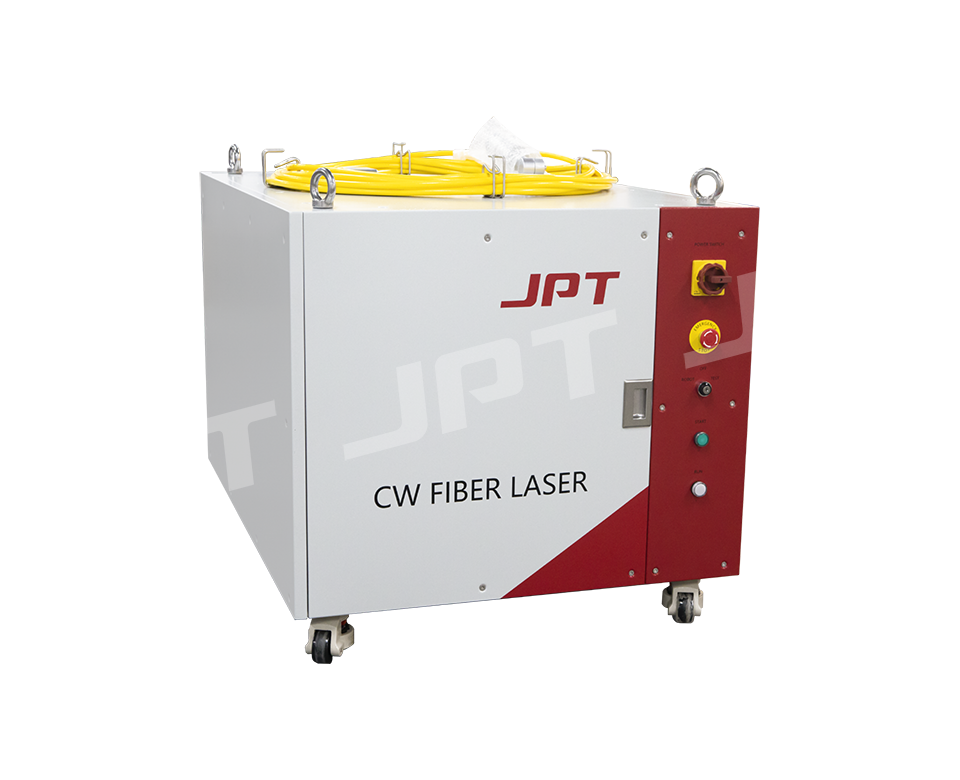

CL 500W~1000W

CL 500W~1000W

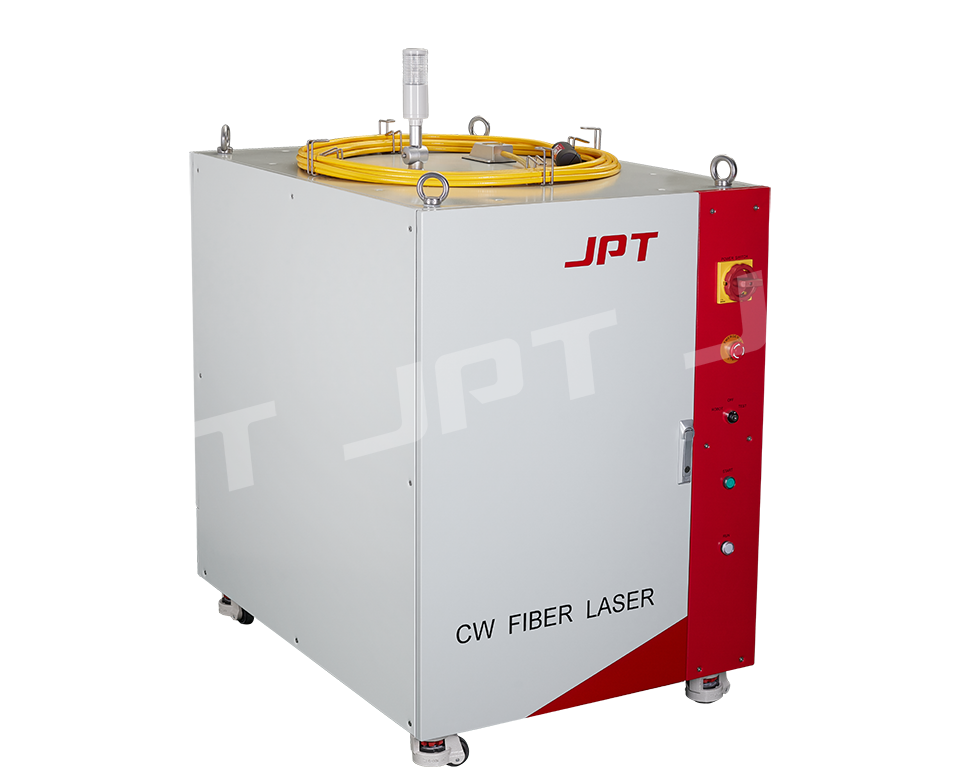

CL 2000W

CL 2000W

Multi-Module CW 6000W

Multi-Module CW 6000W

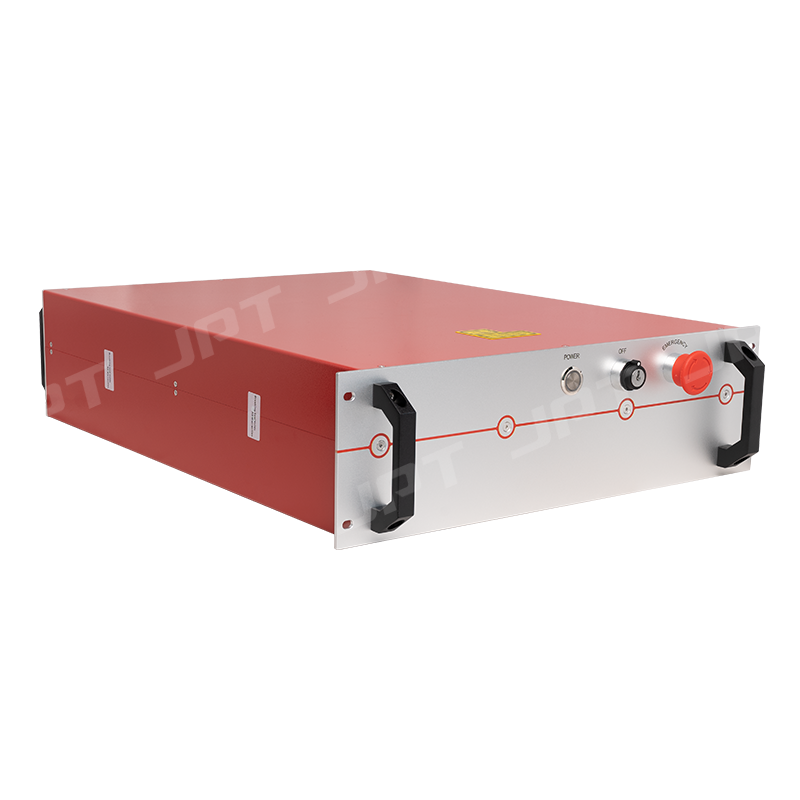

QCW 150W/1500W

QCW 150W/1500W

Multi-Module CW 12000W

Multi-Module CW 12000W

Single-Module CW 1500W-3000W

Single-Module CW 1500W-3000W

SEAL 355-3/5

SEAL 355-3/5

SEAL 532

SEAL 532

LARK 355-3/5

LARK 355-3/5

PS IR/GR/UV Picosecond Laser

PS IR/GR/UV Picosecond Laser

SEAL 355-10/15/20/30

SEAL 355-10/15/20/30

Semiconductor Laser with Red Light Series 200W

Semiconductor Laser with Red Light Series 200W

450nm—100W High Power Diode Laser

450nm—100W High Power Diode Laser

10W-1064-01 Silicon Transmission Series Detection Moduler

10W-1064-01 Silicon Transmission Series Detection Moduler

1060nm Series

1060nm Series

880nm Series

880nm Series

808nm Series

808nm Series

976nm Series

976nm Series

915nm Series

915nm Series

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor Laser

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

Single Chip Resistor Tester

Single Chip Resistor Tester

Laser Trimmer

Laser Trimmer

Hybrid Trimmer

Hybrid Trimmer

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

Six-sided Inspection Machine

Six-sided Inspection Machine